The Overlooked Side of Millwrighting: How Electrical Expertise Powers Industrial Reliability

When most people hear the term millwright contractor, they think of mechanics who align conveyor belts, move massive machinery, or weld steel frames into place. That reputation is well-earned — but it’s only half the story.

More Than Wrenches and Welding

In today’s agricultural plants, mining operations, and manufacturing facilities, mechanical strength is inseparable from electrical intelligence. Every conveyor, crusher, or automated line depends on motors, drives, and wiring systems working seamlessly with the physical equipment. When those electrical systems fail, downtime isn’t measured in minutes — it’s measured in thousands of dollars lost per hour.

That’s why modern millwrights aren’t just mechanical specialists. They’re also trained in industrial electrical repair, design, and integration — ensuring the equipment they install or maintain doesn’t just move, but keeps moving safely, efficiently, and reliably.

Electrical Repairs in Heavy Industry

The electrical demands of industrial operations in Saskatchewan, Manitoba, and Alberta are unique. Grain elevators run for months during harvest without pause. Mining crushers endure dust, vibration, and load surges. Assembly lines push the limits of automation to meet market demands. In all these cases, electrical systems are the hidden backbone.

Common Electrical Challenges Millwrights Solve

Motor Failures: Motors driving conveyors, augers, or pumps are prone to bearing wear, overheating, or electrical winding breakdowns. Millwrights can not only replace the motor but also test and verify its electrical supply, controls, and grounding.

Faulty Sensors & Limit Switches: A misaligned or shorted sensor can bring an entire line to a halt. Millwrights trace wiring, replace components, and re-calibrate systems to restore productivity quickly.

Control Panel Failures: Dust, vibration, and humidity wreak havoc on control panels. Millwrights diagnose burnt relays, short circuits, and overloaded breakers, ensuring compliance with CSA/NEC electrical codes.

Wiring Damage: In plants with heavy equipment, wiring is often subject to abrasion, rodents, or accidental impact. Millwrights reroute, repair, or replace wiring runs to maintain safety and uptime.

Power transmission: Custom industrial power services can be provided by millwrights to ensure clean, ample power is delivered to the equipment that require it.

By combining mechanical and electrical troubleshooting skills, millwrights reduce delays that often happen when multiple contractors are called in. A millwright team can identify whether the failure is mechanical, electrical, or both — and fix it without waiting on a separate trade.

Custom Electrical Design & Integration

Repairing is one side of the equation. The other is custom electrical design and integration — a service that is becoming increasingly valuable as plants modernize.

Building Smarter Conveyor Systems

Conveyors in agriculture, food processing, and mining aren’t just about moving material. They require:

Variable Frequency Drives (VFDs): to optimize energy usage and adjust speeds.

Safety Interlocks: to prevent accidents during maintenance or emergencies.

Load Sensors: to avoid jams or overloading.

Millwrights design and wire these systems from the ground up, ensuring they are integrated into existing plant controls.

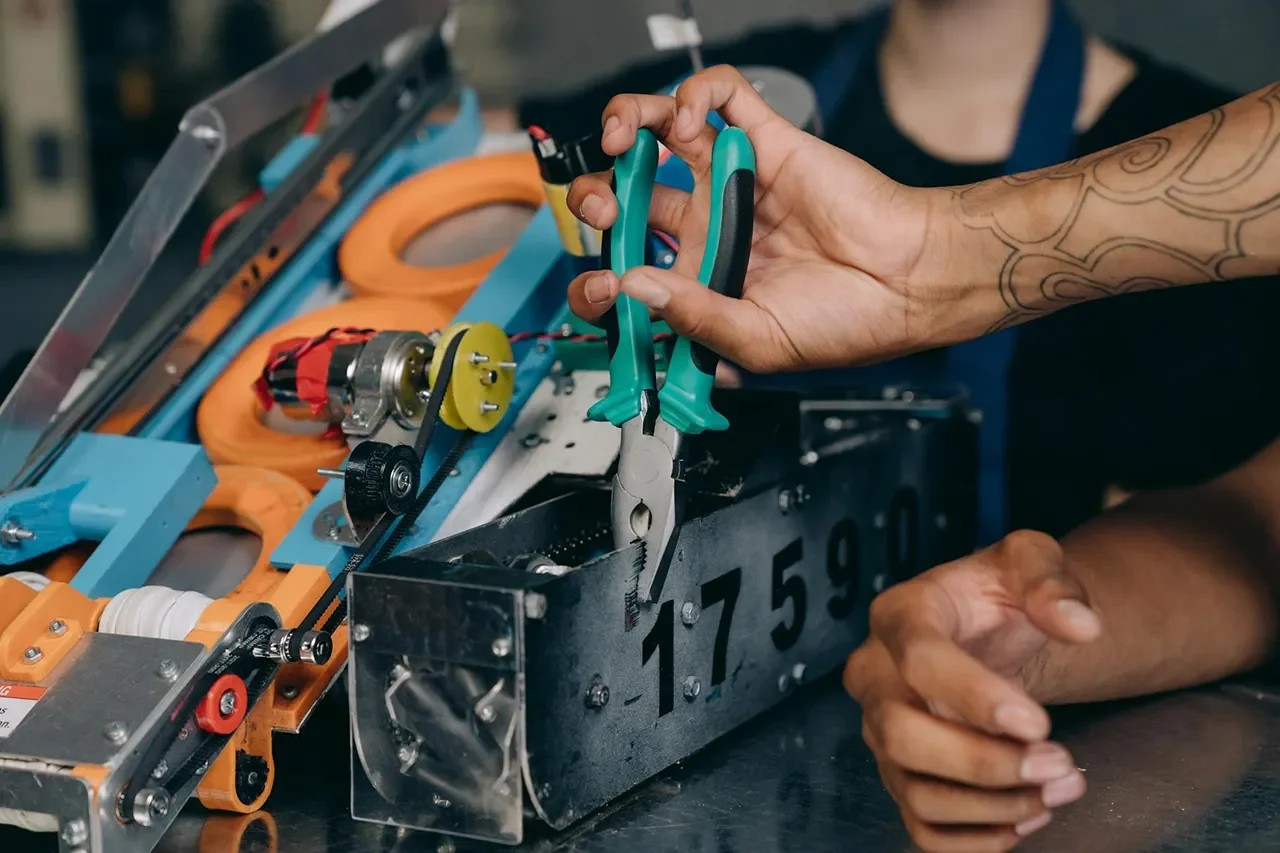

Control Panel Fabrication

Instead of relying on out-of-the-box solutions, millwrights build custom control panels (combining both custom metal fabrication and wiring) that match a facility’s specific requirements. Whether it’s a compact grain elevator with limited power supply or a large mining conveyor system needing multiple start/stop stations, millwrights design panels with:

Proper breaker sizing and overload protection.

Programmable logic controller (PLC) interfaces for automation.

Expansion room for future plant growth.

Retrofitting Legacy Equipment

Many facilities in Saskatchewan and Alberta still rely on older machinery. Millwrights upgrade these systems with modern electrical components such as soft starters, digital control systems, and upgraded wiring harnesses. The result? Improved reliability, lower energy consumption, and compliance with modern electrical safety standards.

Why Choose Millwrights for Electrical Work (vs. Separate Contractors)

Traditionally, facilities might call an electrician for wiring issues and a millwright for mechanical breakdowns. But in practice, these problems rarely exist in isolation. Choosing millwrights who also specialize in electrical services eliminates costly inefficiencies.

1. Integrated Troubleshooting

Instead of finger-pointing between trades, millwrights can identify whether a conveyor stoppage is caused by a seized bearing or a shorted motor circuit — and resolve both.

2. Time & Cost Savings

Downtime in mining or agriculture can cost tens of thousands of dollars per day. Having one team address both mechanical and electrical issues reduces delays.

3. Safety & Compliance

Qualified millwrights follow strict safety standards:

Lockout/tagout procedures for both electrical and mechanical hazards.

CSA/NEC compliance in electrical wiring and grounding.

Machine guarding and interlock verification to prevent operator injury.

4. Long-Term Adaptability

Plants expand, conveyors are extended, new motors are added. Millwrights who understand both systems can expand electrical capacity while upgrading mechanical infrastructure — ensuring everything scales together.

Case Study: Modernizing a Conveyor System

Consider a grain handling facility in southern Saskatchewan. The plant relied on a 30-year-old conveyor system with outdated starters and undersized wiring. Breakdowns were frequent, causing costly harvest delays.

The millwright team:

Replaced Motors: Installed high-efficiency motors sized to load requirements.

Upgraded Wiring: Routed new CSA-rated cables with improved protection.

Installed VFDs: Enabled precise speed control, reducing wear and energy use.

Built a New Control Panel: Integrated overload protection, emergency stops, and PLC-ready expansion ports.

The result? The plant saw 40% fewer stoppages, a 15% reduction in energy costs, and increased throughput during harvest.

Future Trends: Smart Automation & Electrical Monitoring

The industrial electrical role of millwrights is expanding rapidly with the adoption of smart technologies.

Predictive Maintenance with Sensors

IoT-enabled sensors can monitor motor current, vibration, and heat signatures in real time. Millwrights install and configure these systems, allowing plants to predict failures before they happen.

Integration of SCADA Systems

Supervisory Control and Data Acquisition (SCADA) systems connect multiple conveyors, pumps, and machines into a central dashboard. Millwrights wire, program, and integrate these systems for easier plant-wide monitoring.

Renewable Energy Integration

In agriculture, solar and wind systems are increasingly supplementing traditional power. Millwrights play a role in wiring hybrid systems that power conveyors, augers, or irrigation equipment with renewable inputs.

By staying ahead of these trends, millwrights ensure manufacturers don’t just meet today’s needs but prepare for tomorrow’s innovations.

Finally: A Complete Partner in Industrial Reliability

For manufacturers, mines, and agricultural processors in Saskatchewan, Manitoba, and Alberta, downtime is the enemy and reliability is the goal. While mechanical skill has always been the hallmark of millwrighting, the electrical expertise these professionals bring is just as critical.

From diagnosing motor failures to wiring new conveyor systems, from designing control panels to integrating smart monitoring systems, millwright companies provide full-spectrum support. They don’t just move equipment — they power it, protect it, and future-proof it.

In an industrial landscape where efficiency, safety, and uptime are everything, millwrights are not just contractors — they are partners in your long-term success. Across the prairies, consider Saskatchewan’s own Custom Millwright Services for your industrial equipment maintenance and electrical services.