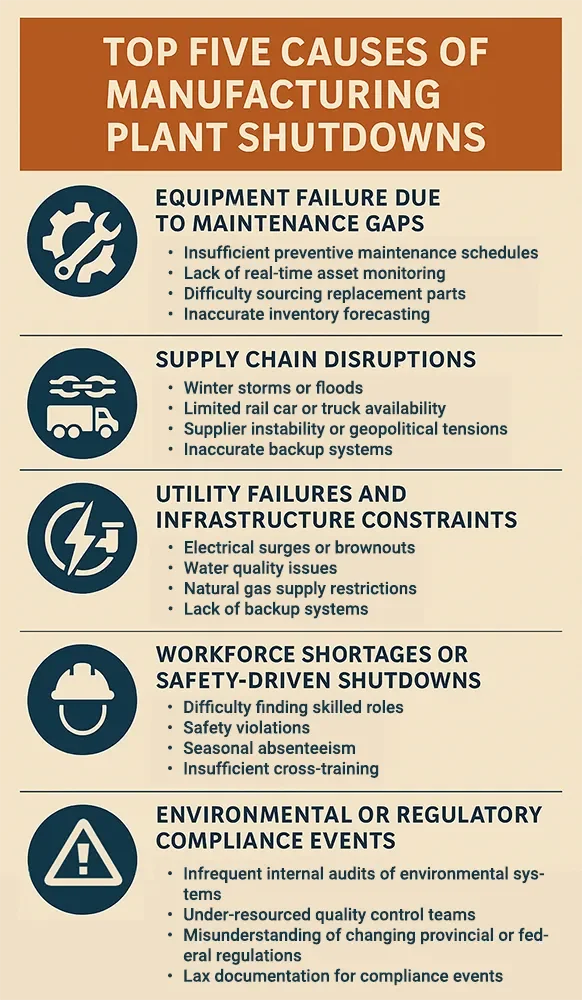

Top Five Causes of Plant Shutdowns (Prairie Provinces)

TL;DR: Shutdowns don’t just eat into your schedule — they eat into your budget and your reputation. And if you’re running a plant in the Prairies, you already know the margin for error is razor thin. Whether it’s a conveyor that fails mid-run, a supply delay that leaves you idle, or a utility hiccup that knocks out production, every unplanned stop costs more than you expect.

We’ve broken down the five most common reasons plants like yours go down — and more importantly, what you can do to keep your operation running. This isn’t theory. It’s what we see, fix, and prevent in real plants, every week. Take these steps, and you’ll cut the risk, save the money, and protect your uptime.

Managing a medium-sized manufacturing plant in the Prairie provinces—whether in Manitoba, Saskatchewan, or Alberta—presents a distinct mix of challenges and opportunities. With a strong presence of agricultural equipment manufacturers, food processors, and fertilizer producers, plant managers must continually balance operational efficiency, regulatory compliance, and environmental resilience.

One of the most disruptive events in any manufacturing environment is an unplanned shutdown. These events carry high costs—not just in lost production, but also in equipment wear, workforce disruption, and reputational damage. Understanding the primary causes of such shutdowns is key to mitigating risk and maintaining uptime.

This article presents the top five reasons for plant shutdowns in the Prairie provinces, backed by industry research and regional operating realities.

1. Equipment Failure Due to Maintenance Gaps

Overview:

Mechanical breakdowns remain the number one cause of unplanned downtime. In Prairie manufacturing—especially plants handling grain processing, packaging, or agricultural implements—conveyors, pumps, and milling equipment often run near capacity and in harsh environmental conditions.

Contributing Factors:

Insufficient preventive maintenance services and schedules.

Lack of real-time asset monitoring (vibration analysis, oil particle counts, etc.).

Difficulty sourcing replacement parts for legacy equipment.

Thermal stress during winter (sub-zero start-ups) and summer (overheating risk).

Mitigation Tactics:

Implementing predictive maintenance via IoT sensors.

Using CMMS (Computerized Maintenance Management Systems) to track maintenance history.

Training local technicians to handle basic rebuilds and diagnostics.

Keeping critical spares in local inventory, especially for drive systems and hydraulics.

Clearly understand what in-house factory maintenance services you can provide. Ensure you have researched and formed business partnerships with reputable millwright organizations that offer specific equipment maintenance services. Activate these resources before the next emergency occurs to minimize downtime.

2. Supply Chain Disruptions

Overview:

The Prairie provinces’ dependence on a sprawling, often weather-sensitive transportation network makes them particularly vulnerable to supply chain interruptions—especially for just-in-time operations and imported components.

Contributing Factors:

Winter storms or spring floods delaying inbound and outbound logistics.

Limited rail car or truck availability during harvest season.

Supplier instability or geopolitical tensions affecting imports (especially from the U.S. or Asia).

Inaccurate inventory forecasting due to outdated ERP (enterprise resource planning) systems.

Mitigation Tactics:

Onshoring key suppliers where possible.

Diversifying logistics partners and establishing buffer stock policies.

Scenario-based procurement planning (e.g., what-if analyses for 2-week delays).

Building stronger collaboration tools between procurement and production.

3. Utility Failures and Infrastructure Constraints

Overview:

Power outages, water shortages, and compressed air failures are frequent contributors to production shutdowns. While the Prairie provinces benefit from relatively stable grids, manufacturing hubs in rural areas or industrial parks sometimes face infrastructure limitations.

Contributing Factors:

Electrical surges or brownouts impacting PLCs or VFDs (variable frequency drive motors).

Water quality issues affecting process equipment (common in fertilizer and food production).

Natural gas supply restrictions during peak heating months.

Lack of backup systems for critical utilities.

Mitigation Tactics:

Installing UPS and voltage regulation systems on sensitive control equipment.

Conducting regular utility audits (especially compressed air systems for leaks and efficiency). (Bonus tip: Compressed air system need a strong maintenance program as they can develop leaks that often go undiscovered and increase inefficiencies dramatically.)

Engaging with local utility providers on infrastructure upgrades or capacity notices.

Implementing tiered restart protocols to prevent system overloads after a blackout.

4. Workforce Shortages or Safety-Driven Shutdowns

Overview:

Labour shortages and safety-related incidents are increasingly common contributors to shutdown events in the Prairies. Medium-sized plants often struggle to attract and retain skilled trades due to competition from larger urban employers or oil and gas projects.

Contributing Factors:

Difficulty filling electrician, millwrights, industrial mechanics, service technicians, and automation technician roles.

Safety violations leading to work stoppages or mandated inspections.

Seasonal absenteeism, especially during seeding or harvest seasons.

Insufficient cross-training, leading to critical skill gaps during vacations or illnesses.

Mitigation Tactics:

Investing in apprenticeships and trade partnerships with technical colleges.

Offering incentives for rural relocation and retention bonuses.

Using digital tools to reinforce safety compliance (e.g., real-time hazard reporting).

Conducting succession and coverage planning for each production role.

5. Environmental or Regulatory Compliance Events

Overview:

Agricultural and food-adjacent manufacturing must comply with stringent environmental and food safety standards. Exceeding air emissions thresholds, failing water discharge tests, or receiving citations for sanitation lapses can lead to immediate shutdowns.

Contributing Factors:

Infrequent internal audits of environmental systems.

Under-resourced quality control teams.

Misunderstanding of changing provincial or federal regulations.

Lax documentation for compliance events (e.g., missing SDS sheets or maintenance logs).

Mitigation Tactics:

Scheduling mock audits and walkthroughs with internal teams and consultants.

Investing in automated environmental monitoring systems.

Keeping abreast of CFIA, Health Canada, and provincial Ministry of Environment bulletins.

Digitizing regulatory paperwork to ensure accessible, real-time tracking.

Closing Thoughts

The industrial heartbeat of the Prairies depends on the reliability of its manufacturing base. For plant managers in medium-sized operations—especially those tied to the agricultural economy—shutdowns are more than a temporary inconvenience; they threaten competitiveness and margins.

By proactively addressing the top five causes of shutdown—equipment failures, supply chain volatility, utility disruptions, workforce issues, and compliance lapses—plants can build resilience and improve uptime. The key lies not just in planning, but in the disciplined execution of maintenance, staffing, and monitoring strategies tailored to the unique conditions of Western Canada.

Custom Millwright Services offers a comprehensive emergency industrial repair services team that can be on-site and diagnosing your problems faster that you might expect. Because their expertise lies both in industrial equipment repairs and solutions (custom engineered for you), you will find that they excel at reducing downtime, maximizing your productivity and finding effective solutions that are utterly cost effective.